Products

THE NAME:

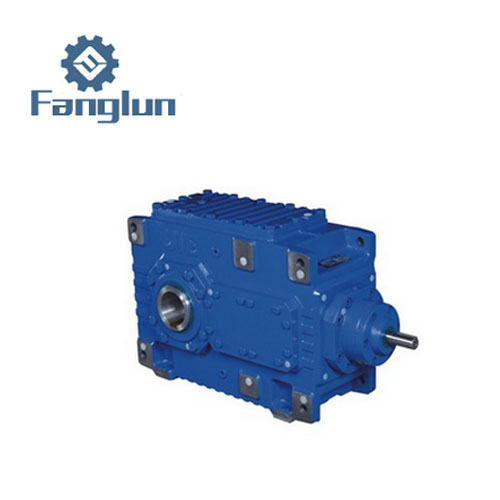

B helical bevel gearbox

Model:

Categories:

Helical geared motor

Place of Origin:

Brand Name:

Description:

B Series High Power Gear Units is a brand-new model of rigid tooth flank gear reducers with wide application areas, which has the feature of large torque range, a design of unit structure modulization capable of horizontal mounting and vertical mounting, three kinds of output shafts — solid shaft, hollow shaft and hollow shaft with shrink disk. With carbureted high -strength good-quality alloy, the series has the feature of high-efficiency and long life-span, high permissible axial and radial loads, low noise, high reliability and compact structure and so on.

B Series High Power Gear Units

Torque Range:Up to 470000N.m

Output speed:1.7~1200rpm

Input power:2.2~5366kw

Mounting solution: foot mounted,shaft mounted,shrink disk mounted.

Input:shaft with key-way,IEC flange;

Output:hollow shaft with key-way,hollow shaft with shrink disk;

Shaft arrangment: A,B,C,D (detailed please see catalogue)

B Series High Power Gear Units Characteristics:

1.Housing material:HT250 high-strength cast iron ;

2.Housing hardness:HBS190-240;

3.Gear material:20CrMnTi alloy steel,other materials requested:17CrNi2Mo,20CrNi4A

4.Surface hardness of gears:HRC58-62;

5.Gear core hardness:HRC33-40;

6.Input / Output shaft material:42CrMo alloy steel;

7.Input / Output shaft hardness:HRC25-30;

8.Heat treatment:tempering,cementiting,quenching.etc.;

9.Machining precision of gears:accurate grinding, 6-5 Grade;

10.Noise (MAX):60~68dB;

11.Lubricating oil:GB L-CKC220-460, Shell Omala220-460;

12.Temp. rise (MAX):40°C ;

13..Efficiency:94%~96% (depends on the transmission stage) ;

14.Temp. rise (Oil)(MAX):50°C;

15.Backlash:≤20Arcmin;

16.Vibration:≤20μm;

Relate Products

Product Catalogue

Fanglun Reducer

- Presicion planetary gearbox

- Worm gearboxes

- Helical geared motor

- Helical hypoid gearbox

- Speed variator

- Industry planetary gearbox

- Cycloidal speed reducer

- Shaft mounted reducer

Fanglun Motor